Sustainability

Arthur Weber AG is committed to sustainable climate protection out of conviction.

By voluntarily participating in the programme of the Energy Agency for Industry, Arthur Weber AG is committed to actively reducing CO2 emissions and optimising energy efficiency.

The target agreement is recognised by the federal government, cantons and partners in the economy.

Rail traffic

Raw materials are delivered by environmentally friendly rail. This not only saves CO2, but also relieves traffic in the region and leads to a higher quality of life for local residents.

Last year, Arthur Weber AG was able to reduce its carbon footprint at the Seoul site through rail transport with SBB

Cargo Schweiz, Arthur Weber AG was able to save around 3,248 lorry journeys at the Seewen site last year.

In this way, Arthur Weber AG avoided approx. 715 t of CO2 emissions in the period from 01.01.2021 to 31.12.2021.

PV systems

Sustainability & ecology

Our products and productions are very space-intensive, which is why we are dependent on large buildings. The roofs are often predestined for the installation of PV systems.

In Seewen, we already commissioned a PV system with an output of around 300Mwh per year in 2012.

The PV system in Schattdorf produces 166Mwh of electricity per year. We use this energy exclusively for our own on-site production and can thus cover almost 70% of our energy needs.

We are striving to equip more suitable roofs of our buildings with PV systems in the future. Sustainability is a major concern for us, which is why we produce and sell high-quality and durable products. Our products should also be increasingly circulated with environmentally friendly energy.

In Schattdorf, we implemented a new PV system on the roof of the 2021 production hall.In Schattdorf, we implemented a new PV system on the roof of the 2021 production hall.

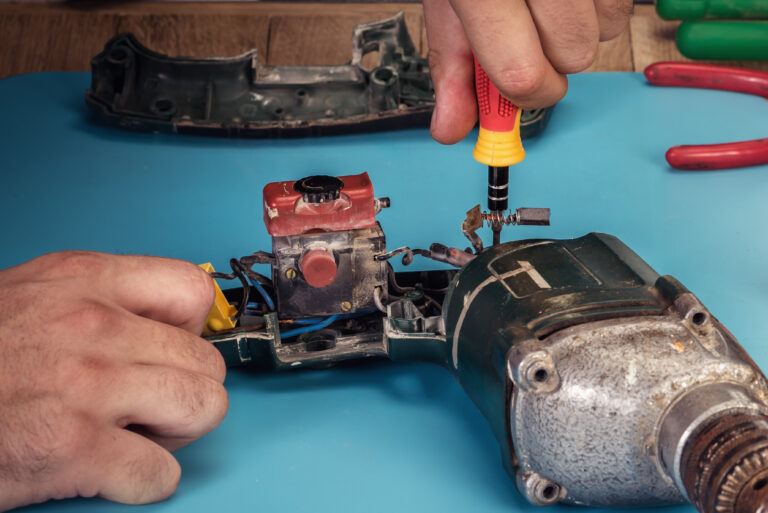

Repair shop

Our repair workshop in Schattdorf repairs your electrical machines and tools so that defective or damaged devices are not unnecessarily disposed of. Two of our employees turn defective tools into perfectly functioning devices again whenever possible.

We also have replacement tools available for urgent cases at any time.

Ausbildung

Arthur Weber AG trains apprentices in a wide range of professions. We attach great importance to training so that well-trained specialists can continue to drive the company forward after the apprenticeship.

High quality products

Our own tool brand Starch, developed in Switzerland, comprises very high-quality products that have a long service life. The material and workmanship are of the highest quality. In this way, we want to prevent tools from becoming defective after a short period of use and having to be disposed of.

Intelligent light control

Wherever possible, we use intelligent lighting control systems in our company. Various motion detectors on the lamps ensure that light only burns where it is needed. The light is also automatically dimmed if no movement is detected in the room. In this way, we avoid unnecessary power consumption.